Slightly less than a year ago the residents of one of the hottest states in the country woke up to find their power out, pipes burst and icy havoc everywhere. The big freeze that hit Texas, February 13, 2021 and lasted almost a week, killed more people than the Alamo and racked up billions of dollars in damages.

That should be warning enough to take winter seriously. Whether it’s your tools or equipment you should understand the worst that could happen and prepare for it. Here’s a checklist of the dangers and what you can do to prevent them.

The #1 Rule

No set of rules could possibly cover all the contingencies for different brands and types of equipment, mobile, stationary, rubber-tire, tracked, low and high horsepower, diesel, gas, hybrid or fully electric. So the #1 rule is to check with the equipment dealer or OEM or consult the manual first.

Also don’t do this slapdash or just whenever you get around to it. Use our list here as a starting point but then study your equipment and needs, develop an action plan and then execute—before it’s too late.

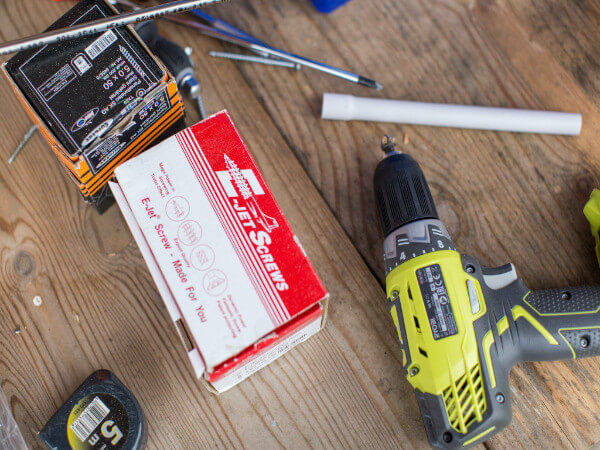

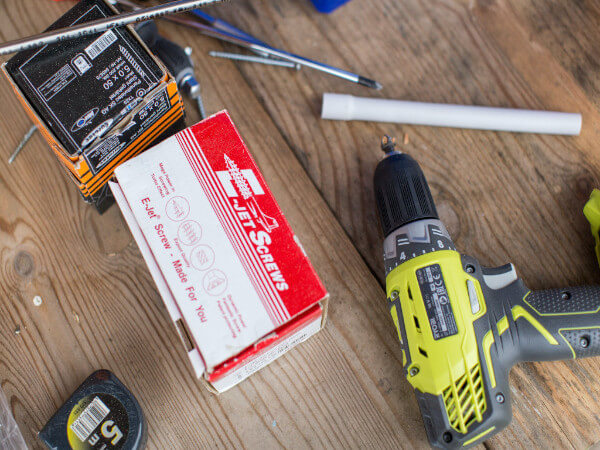

Power Tools

The rechargeable batteries used to run saws, drills, flashlights and even some demolition tools should never be left out in cold weather. Below 40 degrees lithium-ion batteries won’t hold a charge and leaving them out in freezing temperatures can permanently reduce run time. Don’t store these in an unheated shop, or your truck toolbox when freezing weather threatens.

If you build a charging station to hold these tools, batteries and chargers, make it portable so you can bring it inside when necessary and always keep the batteries and tools within the temperature range recommended by the manufacturer.

Pneumatic Tools

Air-driven power tools such as DA sanders, nail guns rely on seals, O-rings and lubrication to function properly. When cold temps turn these materials brittle or cause the lubrication to gel, they won’t fire properly and may become permanently damaged. Always store them inside at the temperatures recommended.

If using them outside in freezing weather, follow manufacturer guidelines. If needed you can rotate tools from outside to inside throughout the day to keep them functioning properly. Also, consider using a cold-weather lubricant/pneumatic tool oil.

Compressors

Air compressors will accumulate moisture over repeated exposure to rising and falling temperatures. Make sure you drain the compressor at the end of every day. Use air hoses that remain flexible in the cold and consider using an in-line antifreeze product such as Kilfrost Pneumatic Tool and Antifreeze lubricant to prevent blockages.

Shop Heat

Shops without a dedicated HVAC system will sometimes use gas or propane forced air heaters to warm up the work environment. Be sure you follow all the manufacturer’s instructions on ventilation when using these. And note that these sometimes create a thin film on many surfaces. You won’t be able to see this film and it won’t affect most operations but it may prevent spray paint from adhering to surfaces should you want to paint anything that’s been stored in the shop. Extra degreasing on metal surfaces should alleviate the problem.

Electric space heaters are sometimes used for small spaces, just be aware that these will increase your power bill considerably.

Gas Engines

There is considerable debate among construction and landscaping professionals about how to store gasoline-powered tools for the winter. One camp says to drain the tank, completely, shoot a small squirt of lube oil in the spark plug hole and pull the starter rope a few times to coat the inside of the engine with oil. Others say to fill the tank with gasoline that’s been treated with an additive.

Our advice: do whatever the owner’s manual says to do. If you don’t have the manual most manufacturers post them online.

As winter’s shortened days close in, operators and foremen are tempted to keep working into the dusk. Before this happens check all the lights on your machines to make sure they’re in good working order.

Consider adding auxiliary lighting packages—today’s new LED lights can provide amazing illumination while also conserving battery power. And put a towel inside every machine so operators can clear the windshield of any condensation that occurs.

Diesel Engines

A long time ago contractors would start their diesel engines early, and do something else for five or ten minutes to let the engine warm up before driving off or starting work. And in cold weather, they’d also leave their diesels running for fear of them not starting back up. That’s no longer the case.

Today’s diesels need only a minute or so to warm up and they have sufficient battery power to restart even in the coldest temps. Running a diesel engine at low idle for long periods of time can actually cause carbon accumulation in the engine as the exhaust after-treatment process doesn’t get hot enough to burn it off. Go ahead and start working within 60 seconds of startup. Your engine and its DPF and/or DOC systems will thank you for it. For extremely cold weather (states bordering Canada), you may need a cold weather starting package that your OEM dealer can provide.

Newer machines and trucks generally run with low viscosity lube oils to improve fuel efficiency. The new 5W-40 and 0W-40 synthetic will perform well down to -20 degrees Fahrenheit. But if you are running thicker oils in your older equipment, check with the OEM before switching to low viscosity.

Keep it Clean

While you still have above-freezing temperatures pressure wash your equipment, paying extra attention to tracks and undercarriages. If ice or frozen mud is left on those, it will lock up the whole undercarriage and you will not be able to move the machine until it thaws out. And even if you do get it moving you could be damaging the pins, bushings and rollers unless all the frozen gunk is removed first.

Dirt and frozen crud will also hide leaky seals and components that if left unattended could create maintenance headaches down the line. Salt and other road-de-icing chemicals can also cause rust and corrosion if left on the machine for long.

Move it

Even if you’re parking your machines for the winter, it’s a good idea to periodically start them, move the joysticks, and travel a short distance. This keeps seals and fittings coated with lubrication and prevents ice build-up that might compromise operation when you need the machine.

Pushing fluid through the hydraulic system will keep valves and seals lubricated and in good shape. Also lubricate door hinges and other metal-to-metal parts to keep them swinging freely, ward off moisture and prevent rust.

Tires and Hoses

Repeated cold, thaw cycles can create small, temporary air leaks between the rim and sidewalls of your truck and equipment tires. Over the course of a few days this can lead to a loss of as much as 20 to 40 percent of the air pressure in your tires. Be sure to check your tires after the first hard cold snap and adjust the psi if necessary. Cold weather can also make tires brittle and more prone to damage, so tread lightly in operation.

Rubber hoses are also subject to brittleness and cracking or loosening up from their fittings in cold weather. Be sure to inspect these carefully before operation.

DEF Maintenance

Diesel exhaust fluid is mostly water, and it can freeze at 12-degrees Fahrenheit. Today’s Tier 4 and Tier 4 Final engines either have DEF system pre-heaters or will allow you to run them for a few minutes until the DEF in the lines and reservoir thaw out. But keep an eye on it. If it doesn’t thaw out, the engine could derate. If problems occur, call your dealer’s service department.

If you intend to store your machine in sub-freezing weather, drain the DEF reservoir. Upon restarting in warmer weather flush the DEF system with distilled water. And be sure you keep your bulk storage of DEF somewhere it won’t freeze. Otherwise, you won’t be able to dispense it.

Fuel

Number 2 diesel works fine in the warmer months and it is less expensive, but the hydrocarbons in diesel fuel can begin to gel when it drops below 40 degrees. Number 1 diesel (which you can buy at truck stops or specify from your fuel supplier) has a lower viscosity and is less likely to gel.

At the end of the day in any cold temperatures, it’s wise to top up your fuel tanks to avoid condensation and water. Use cold weather fuel additives when necessary but always make sure to check with the OEM or dealer on what additives to use. There’s a lot of snake oil out there. An engine block heater can alleviate some of these gelling problems by keeping the engine, fuel lines and injectors at a more favorable temperature when the machine is not running.

Lubes, Grease and Fluids

Prolonged cold temperatures may adversely affect engine oil, grease and hydraulic fluid making them less viscous and harder to pump. Check with your OEM dealer about best practices in your area and change these fluids before problems emerge.

If your regular grease gets too cold, it may block the lines and make it impossible to push low-viscosity/low-temp grease into the lines. Conversely, when temperatures start to rise, change back to your normal fluid regimen to prevent low-viscosity fluids from damaging your equipment.

Hydraulic Cylinders

If you intend to store a machine for the winter, spray a protective coating on the chrome to guard against rust. Even faint surface rust creates enough pitting to cause cylinder seals to leak when you start back up.

Battery Care

Heavy equipment and truck batteries do not like cold weather. Check the terminals and connections to make sure they are tight and corrosion free. Coat the battery clamps with dielectric grease to prevent mineral deposits or corrosion.

Left outside, batteries can freeze and take up to 30 hours to thaw. If that is a risk, use a battery blanket to keep your battery above 32 degrees. Have your battery and alternator tested before the cold season begins to make sure both can perform up to spec.