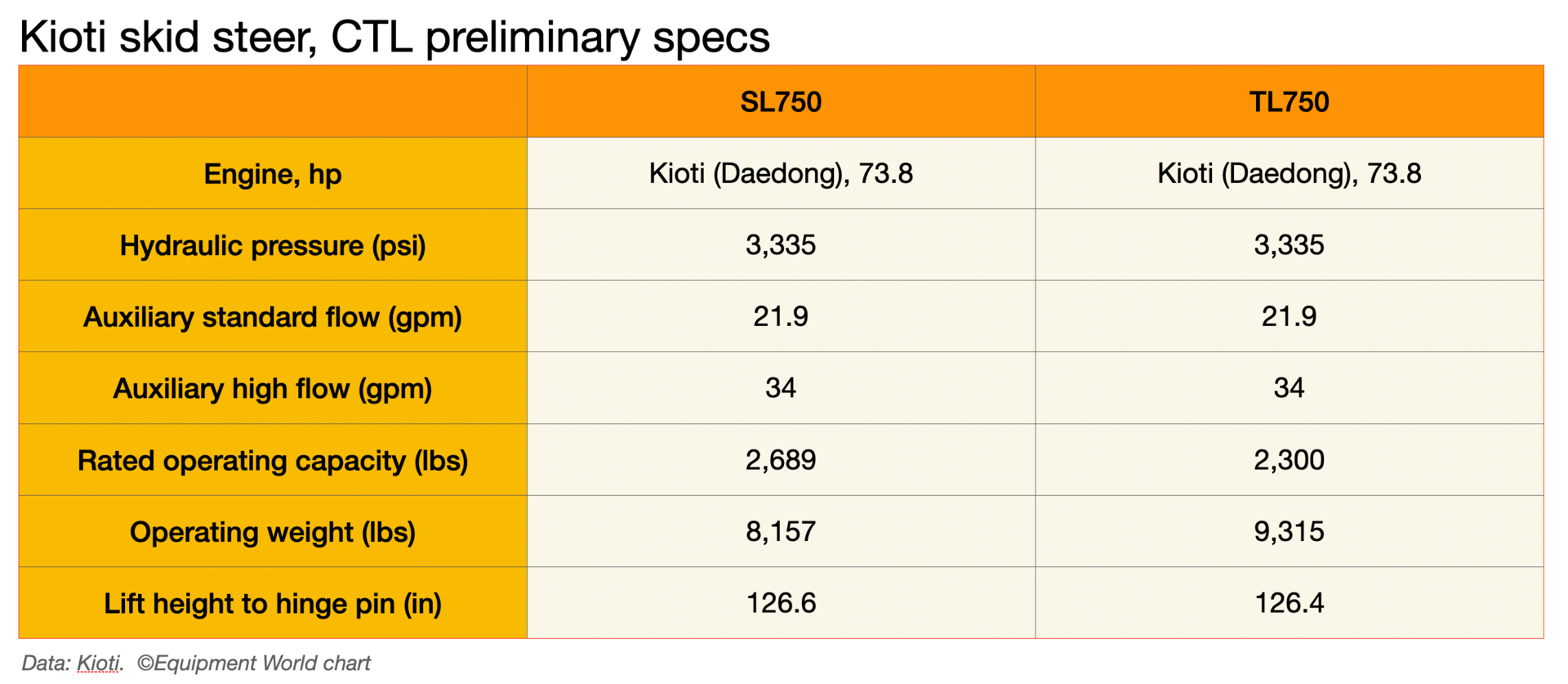

At the recent GIE + Expo, Kioti Tractor took the wraps off its new skid steer loader, which it expects to have in dealers’ hands by the second half of next year.

Along with a coming compact track loader that it also announced at its dealer meeting late last year, the skid steer represents Kioti’s coming foray into compact equipment. The two machines will expand its equipment offering beyond the utility tractors, UTVs and lawn mowers now on the Daedong-USA subsidiary’s product list.

Kioti also indicates that a compact excavator may be forthcoming. “We have a roadmap and mini excavators are something we’re looking at as well as other platforms that are hot right now,” says Greg Bibee, Kioti director of strategic sales and marketing, in an interview with Equipment World.

Kioti has hired Jason Boerger, formerly Bobcat’s excavator marketing manager, as its compact construction product manager.

“Having Jason on board is part of our journey into more compact construction equipment and building the team around it,” Bibee says. “This goes beyond just the equipment we are going to launch initially.”

Initial products

Kioti says it’s still finalizing the base and optional features of the SL750 skid steer and TL750 CTL, which will be launched in “a couple of different versions,” says Bibee.

As indicated in last year’s release, the SL750 and TL750 (both model names are still preliminary, by the way) will be powered by a 74-horsepower Kioti engine, which comes from the firm’s South Korean parent Daedong.

“It will be a similar engine to what we use in our RX Series of tractors,” Bibee says.

The initial versions will have full cabs although an ROPs option is likely. “We’re still evaluating the potential take rates of certain features and options,” says Boerger. The entry door on the vertical-lift units will slide up instead of opening to the side.

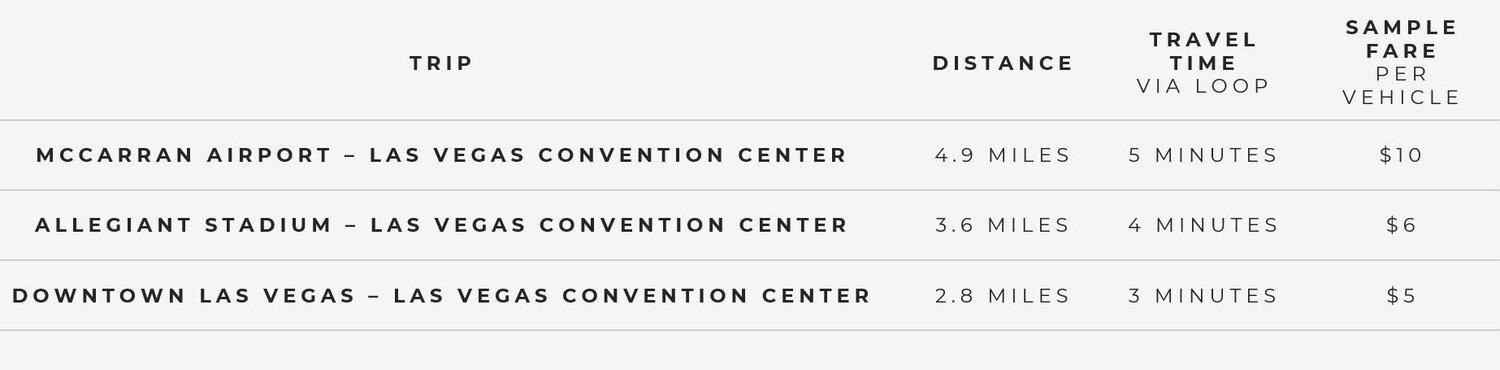

Additional recently released specs include a hydraulic pressure of 3,335 psi, auxiliary standard hydraulic flow of 21.9 gallons per minuteand high flow for both machines of 34 gpm. (Additional specs are in the chart below the article.)

Kioti cautions that the second half of 2022 timeline for these products is also dependent on global supply chains settling down to at least a somewhat normal delivery schedule. Both machines will be manufactured in South Korea.

Why enter a crowded market?

The Kioti SL750 skid steer and TL750 compact track loader.Kioti Tractor

Bibee says Kioti gets asked this question a lot. The simple answer is that it’s the logical next step in the company’s growth. The company entered the U.S. market in 1986, offering under-100-horsepower utility tractors. It added utility vehicles in 2015 and introduced a zero-turn mower line in 2019.

“We’re looking at both our dealer network and current customer base and seeing what products would bring new customers into their stores,” Bibee says. “For our current customers, it gives them more types of equipment.”

Bibee says there are similarities with the company’s recent foray into turf care and the compact equipment effort: both are aimed at professionals in addition to the DIYer or hobby farmer attracted to Kioti’s other products.

Bibee sees Kioti’s coming compact line evolving similarly to its turf care line. “We started with seated zero-turn mowers, where the bulk of the market is,” he says. The company is now offering stand-on mowers and Kawasaki engines. “We’re going to target where we best serve the market and where we feel there’s the biggest opportunity,” he says.

Boerger says he was attracted to Kioti’s strong dealer network plus the opportunity for growth within the construction, landscaping and agricultural markets. “Being able to jump in at ground zero so to speak and help bring the product to maturity is an exciting opportunity.”

“I had a chance to peek at the product early on and was very happy with what I saw, including the company’s attention to serviceability and performance,” Boerger continues. “Kioti dealer-customer relationships are also a strong differentiator.”

Kioti has more than 500 dealer locations in North America. “We’ve got a healthy pipeline right now of new dealers coming on board,” Bibee says.

Not all current Kioti dealers offer the company’s full product range, and Kioti is seeking dealers that have the right business plan, sales strategy, shop facilities and staffing to take on its new construction line.

There is a mix in Kioti’s dealer network, with some dealers tractor only, some offering tractors and turf care and still others that will take on Kioti’s eventual full line. Bibee says Kioti is also looking “at alternative dealer arrangements” where dealers choose on a more line-by-line basis what to carry. “It’s going to be highly dependent on the market and if there’s an opportunity to sell in some hot spots,” he says.

Did you miss our previous article…

https://www.cityheartsaberdeen.com/?p=436